Industrial Coffee Grinder for Mass Brewing: Important Details

Industrial Coffee Grinder for Mass Brewing: Important Details

Blog Article

Industrial Coffee Mill Overview: Boost Performance and High Quality

In the competitive landscape of coffee production, picking the ideal industrial coffee mill plays a critical duty in boosting both effectiveness and product high quality. Recognizing the nuances of numerous mill kinds and vital functions-- such as personalized work setups and robust building and construction-- can substantially influence the last taste profile of the coffee. In addition, the optimization of the grinding process, coupled with thorough upkeep, is crucial for maintaining efficiency in time. As we explore these crucial components, it comes to be apparent that the ramifications extend beyond simple devices choice, affecting overall business success in manner ins which warrant closer examination.

Recognizing Mill Types

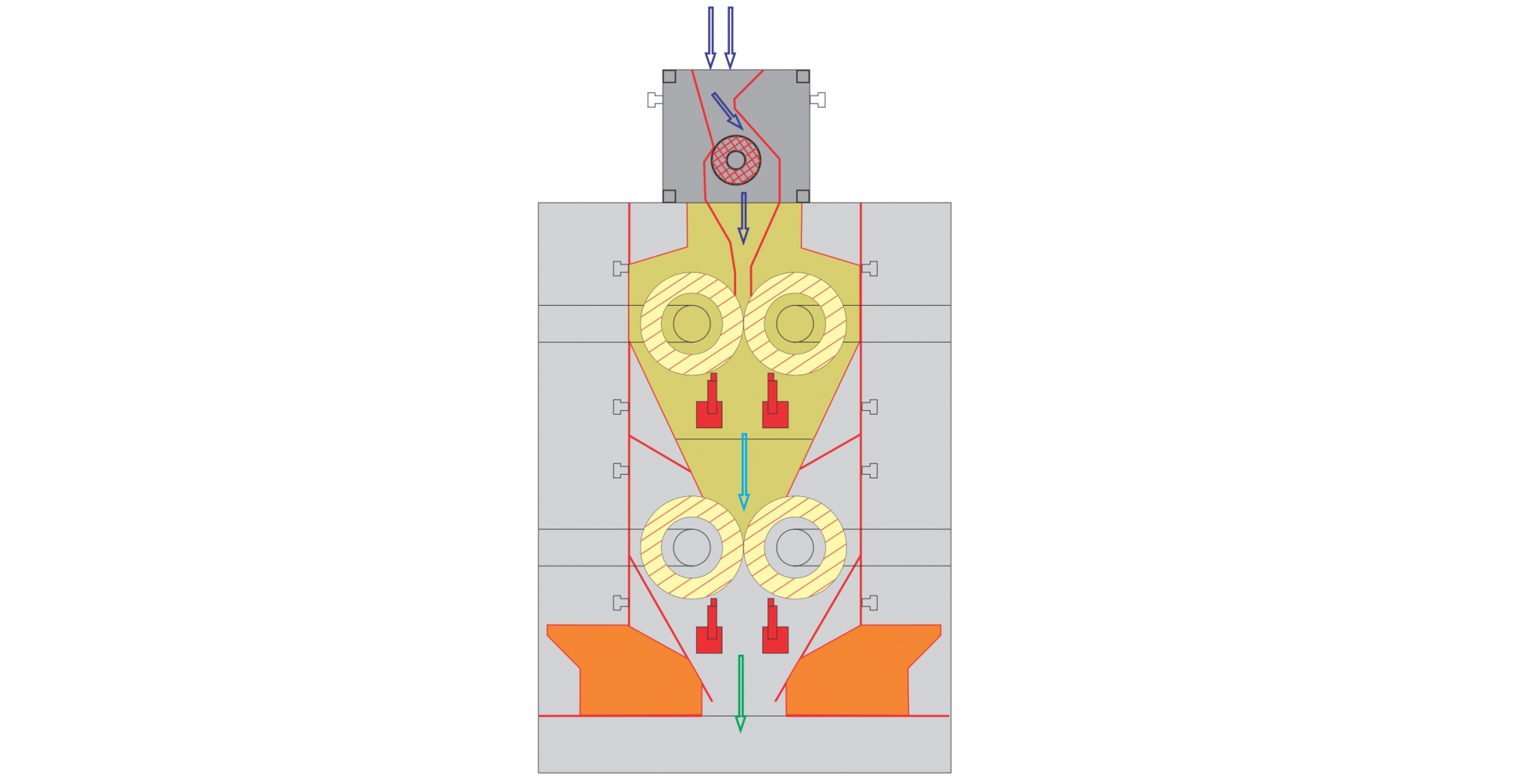

When selecting an industrial coffee mill, understanding the different kinds offered is vital for maximizing both flavor removal and functional effectiveness. The 2 primary types of grinders are blade grinders and burr grinders.

Eventually, picking the right sort of grinder is integral to maintaining quality and performance in coffee production, making it imperative for businesses to purchase top quality burr mills for ideal results.

Key Features to Think About

Selecting an industrial coffee grinder requires cautious factor to consider of a number of key attributes that can dramatically affect both efficiency and the general coffee experience. Among the primary aspects to assess is the grinding system. Burr grinders are typically favored over blade grinders, as they give a constant grind dimension, which is vital for ideal removal and taste.

Another important function is the mill's capability. Depending on the volume of coffee you need to procedure, pick a design that can handle your needs without sacrificing speed or high quality. Additionally, take into consideration the work settings used. A flexible mill with multiple settings enables you to customize the grind size to various brewing methods, improving the coffee's flavor account.

Assess the grinder's noise degree, specifically in a hectic café or manufacturing atmosphere, where too much noise can be turbulent. Spending in a mill that stabilizes these attributes can significantly improve both operational effectiveness and the top quality of the coffee offered.

Optimizing Grinding Refine

To attain why not try this out the very best results in coffee prep work, maximizing the grinding process is necessary. The work dimension substantially affects removal, flavor, and overall top quality of the made coffee. Different brewing techniques call for certain grind dimensions; for example, espresso demands a great grind, while French press requires a rugged appearance. Understanding the partnership in between work size and brewing technique is the very first step in optimization.

Furthermore, keeping track of the grinding speed can maximize the procedure. Slower grinding commonly creates less warm, preserving fragile tastes and fragrances. Conversely, quicker grinding might create excessive warm, negatively influencing the coffee's high quality.

Upkeep and Care Tips

Correct upkeep and care of industrial coffee mills are vital for making certain optimal efficiency and durability. Normal cleaning is the structure of maintenance; residue build-up can influence flavor and grinding efficiency. It is advisable to clean the mill after each use, cleaning down the outside and eliminating any coffee grounds from the burrs.

Furthermore, check the grinding burrs for wear and tear. Boring burrs can endanger work uniformity, so they ought to be changed as essential. Industrial Coffee Grinder. Regularly adjusting the grinder is additionally vital, as this maintains the preferred work you can try these out size for various developing methods

Lubrication of moving components ought to be carried out according to the maker's specs, as this reduces friction and lengthens the life of the equipment. It is necessary to make use of food-grade lubricants to make sure security and conformity with wellness guidelines.

Finally, keep the mill in a stable and dry atmosphere to stop corrosion and corrosion. By sticking to these upkeep and care suggestions, drivers can enhance the effectiveness of their industrial coffee mills while making sure top notch result and expanded operational life.

Return on Financial Investment Analysis

Examining the return on financial investment (ROI) for industrial coffee mills is essential for services seeking to maximize their coffee production capabilities. A detailed ROI evaluation helps identify the financial feasibility of purchasing top notch mills, allowing businesses to consider the initial costs against potential gains.

Analyze the acquisition cost of the mill, consisting of setup and any type of necessary adjustments to existing framework. High-performance mills often lead to minimized grinding time and enhanced throughput, which can dramatically enhance efficiency.

Additionally, take into consideration the effect on product quality. Industrial Coffee Grinder. Superior grinders generate an even more regular grind dimension, which can enhance taste accounts and consumer complete satisfaction, eventually driving sales. By boosting the top quality of the last product, businesses can warrant greater pricing, bring about boosted income

Conclusion

In summary, a commercial coffee grinder plays try this site a critical duty in improving both effectiveness and product top quality within coffee production. Ultimately, the calculated financial investment in a dependable grinder contributes dramatically to enhanced income and competition in the coffee market.

In the affordable landscape of coffee production, selecting the ideal commercial coffee mill plays a pivotal function in boosting both performance and item high quality. The two main types of grinders are blade mills and burr grinders. Within the burr mill classification, there are flat burr mills and cone-shaped burr grinders, each with its benefits. Burr grinders are typically liked over blade mills, as they provide a constant grind dimension, which is critical for optimum extraction and taste.

In recap, a commercial coffee grinder plays an essential function in boosting both efficiency and item top quality within coffee manufacturing.

Report this page